Differences Between the Steel Structure Commercial And Steel Structure Industrial Construction

While both utilize steel as the primary structural material, steel structure commercial and industrial construction differ fundamentally in their purpose, design priorities, technical requirements, and end-user experience.

Here’s a detailed breakdown of the key differences:

|

Feature |

Steel Structure Commercial Construction |

Steel Structure Industrial Construction |

|

Primary Purpose |

To house people and facilitate commerce. Focus on customer experience, retail, office work, and public gatherings. |

To facilitate manufacturing, production, and logistics. Focus on process flow, machinery, and efficiency of industrial operations. |

|

Design & Aesthetics |

High priority. Architectural appeal is critical. Features include sleek facades, curtain walls, glass, and finishes to attract customers and tenants. |

Low to minimal priority. Function over form. Exposed steel, metal siding, and utilitarian appearance are common. Aesthetics are often secondary. |

|

Layout & Floor Plan |

Flexible, divisible spaces (e.g., offices, storefronts). Focus on pedestrian flow, lighting, and creating pleasant environments. Often includes mezzanines for additional leasable area. |

Large, open, and column-free spaces to accommodate production lines, large machinery, and storage racks. Layout is dictated by process flow. |

|

Clear Span Requirements |

Moderate. Typical spans for retail or atria (e.g., 20-40 feet). Some spaces like auto dealerships or warehouses may require larger spans. |

Extremely High. Often requires massive, clear-span spaces (e.g., 100+ feet) for unimpeded movement of cranes, assembly lines, and storage systems. |

|

Floor Load Capacity |

Standard live loads (e.g., 50-150 psf for offices/retail). Designed for people, furniture, and light equipment. |

Very High. Designed for heavy machinery, dense storage racks (e.g., pallet racks), and heavy vehicle traffic (e.g., forklifts). Loads can exceed 500 psf. |

|

Building Systems (MEP) |

Complex. Emphasis on human comfort: advanced HVAC, extensive electrical/lighting, plumbing for restrooms/kitchens, IT infrastructure, fire alarms, and sprinklers. |

Heavy-Duty & Process-Focused. High-capacity electrical for machinery, process-specific plumbing (e.g., compressed air, water lines), industrial ventilation (fume hoods, dust collection), and specialized systems. |

|

Crane & Hoist Systems |

Rare. Limited to small service elevators or freight lifts. |

Very Common. Often includes integrated overhead bridge cranes, gantry cranes, or jib cranes with high load capacities (e.g., 5 to 100+ tons). |

|

Ceiling Height |

Standard heights (e.g., 10-20 feet). Higher ceilings in atriums or flagship stores. |

Very High Clear Height. Often 25-40 feet or more to accommodate vertical storage, large equipment, and crane systems. |

|

Durability & Maintenance |

Durable, but finishes and appearance are maintained. Focus on corrosion resistance for longevity of appearance. |

Extreme Durability. Built to withstand abrasion, chemicals, impacts, and heavy use. Often has simpler, more repairable finishes. |

|

Code & Regulatory Focus |

Life Safety and Accessibility: Strict codes for egress, fire resistance, seismic design, and ADA compliance for public access. |

Life Safety and Process Safety: Includes all building codes plus additional OSHA standards, hazardous material handling, and high-hazard occupancy requirements. |

|

Examples |

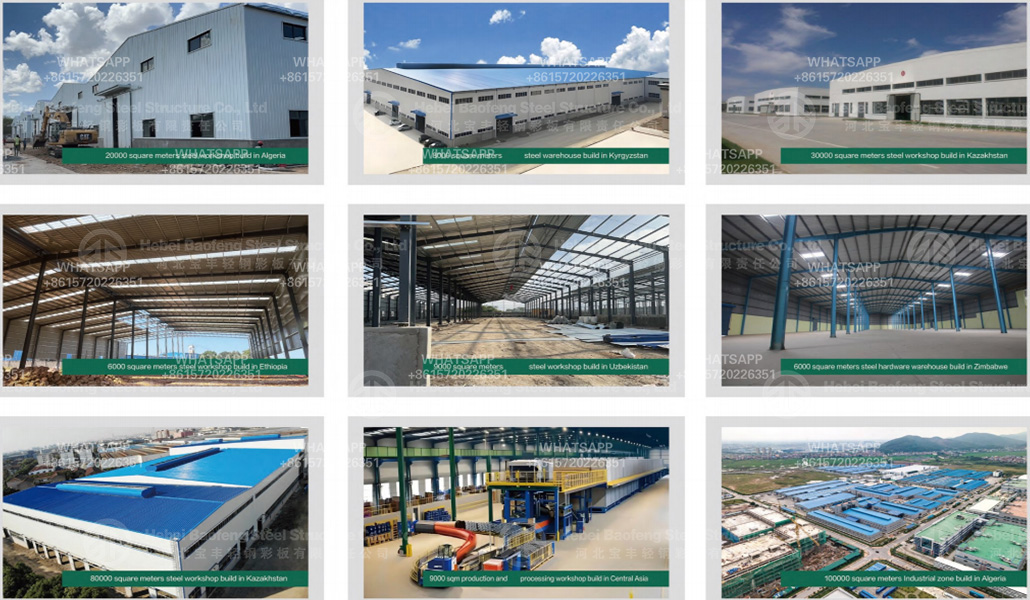

Shopping malls, big-box retail stores, office buildings, sports arenas, airports, car dealerships, entertainment complexes. |

Manufacturing plants, warehouses & distribution centers, aircraft hangars, chemical processing facilities, power plants, recycling centers. |

Summary: Core Philosophy

Steel Commercial Construction: "People-Centric." The building is a destination. The goal is to create an environment that is safe, comfortable, attractive, and efficient for people to work, shop, and gather. Steel is chosen for its speed of construction, column-free spaces, and modern aesthetic.

Steel Industrial Construction: "Process-Centric." The building is a tool. The goal is to create a highly functional, efficient, and durable shell that enables a specific industrial process (making, storing, moving goods) with minimal obstruction and maximum utility. Steel is chosen for its strength, long-span capabilities, and ability to support heavy loads.

Key Overlap (Warehouses/Distribution Centers): This is a hybrid category. A "big-box" store (commercial) and a distribution center (industrial) may look similar structurally. The key difference is in the specifications. The commercial store is built for customer access, parking, and finish; the industrial DC is built for maximum storage density, heavy truck traffic, and robotic systems, with much higher floor loads and simpler finishes.

Kategori

blog terbaru

© hak cipta: 2026 Hebei Baofeng Steel Structure CO.,LTD Hak cipta terpelihara.

IPv6 rangkaian disokong